pick: faster picking, fewer errors

Reducing movements is a great way to improve the efficiency of operators’ work, but it’s not your only option. To go one step further and do away with delivery notes, you could make use ofpick-to-light設備。

藥物實驗室的揀選係統的示例

挑選工作如何?

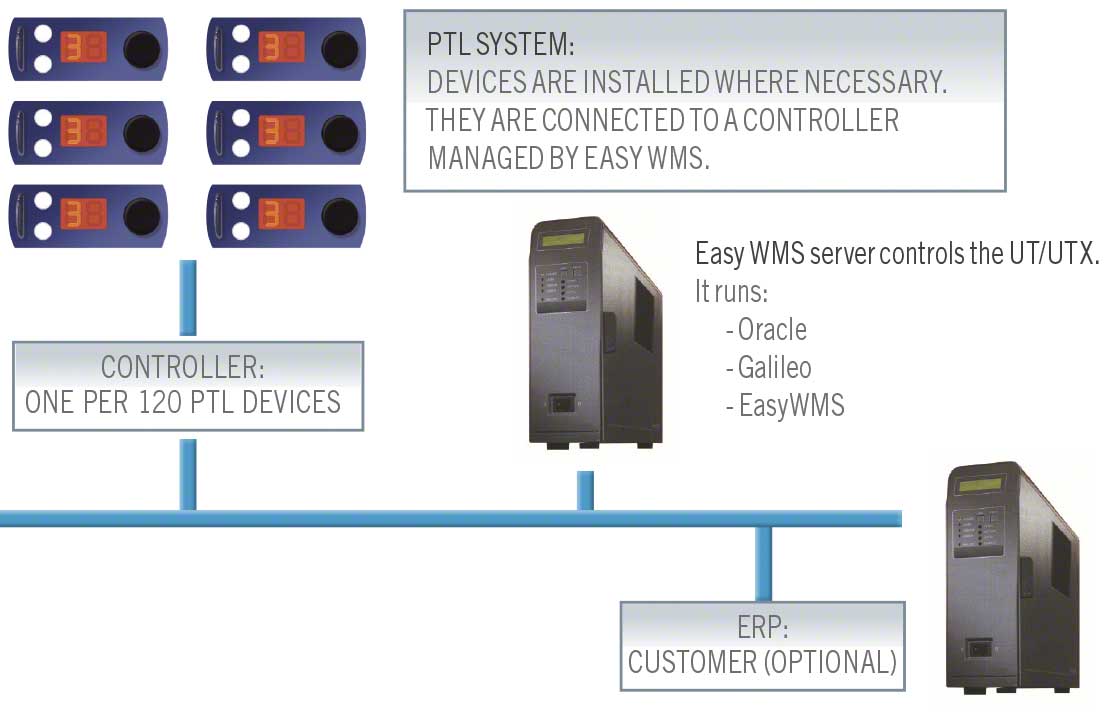

The front of each carton flow channel is equipped with a numerical display with buttons. These devices are controlled by the倉庫管理係統(WMS)。This software lights up the display, prompting the operator to remove goods from that channel and indicating on the screen how many units of the SKU in question to pick.

然後,運營商掃描將收到貨物的位置(這可能是揀選車的架子,箱子或包含訂單的實際包裝)。完成提取相應單元後,工人按下鍵以確認已執行操作。這通知WM,燈光關閉。當需要準備新的訂單時,需要提取產品的新位置被自動照明。

揀貨設備非常多功能,可以使用:

- To preparevarious orders at once, 和one or more operators同時滿足任務(可以為每個工人分配不同的光)。事實上,同時工作的運算符越多,您將為係統製造的更大。

- Withzone pickingmethodologies, since each worker is assigned to a specific area. This eliminates unnecessary movements and limits the number of devices to install.

- 結合自動解決方案,如MiniLoad係統和滾筒輸送機, which streamline the transportation of boxes.

- To complement thepick-to-cartmethod, either because the operators deposit SKUs in picking carts or because the carts are equipped with these types of light-up devices.

Differences between pick-to-light and put-to-light

pick-to-light和put-to-light methods are based on the use of light signals and operate through their connection to warehouse management software. Physical devices, in fact, can be configured tofunction as pick-to-light and put-to-light設備。然而,這兩個方式之間的差異在於操作的排序:

- Pick-to-light system:

The display lights up, indicating哪些產品需要從架子中提取。一旦操作員拾取它們並將它們存放在相應的容器中,燈會關閉。一般來說,包裹由一個移動盒子的輸送機located in the main aisle or below the挑選貨架本身。

Oneexample of an installation that implements pick-to-light in this way is that of AS Healthcare(Arvato Bertelsmann)由MeCalux設計。

- Put-to-light system:

利用投放係統,發光顯示屏顯示每個包裝或架子上的每個封裝或箱子的標準數量。因此,該係統在此期間非常有用replenishment phase。它也用作輔助揀選的設備。

In this vein, put-to-light can serve to streamline the final stage of order prep. The operator picks products, placing them in a box on the shelf while guided by the put-to-light system. Once the goods have been placed in the box, the worker presses the button, switching off the light.

這種壓縮的實施通常也與使用輸送機和其他的使用相結合自動係統,如MiniLoads或AS / RS堆垛機起重機。在這種情況下,堆疊器起重機將執行揀選。一旦收集所有SKU,運營商將把它們安排在隨後派遣的包裝中。此采摘模型遵循installation Mecalux set up for Groupe Rand in France。

When should I use pick-to-light at my warehouse?

挑選設計為:

- 具有非常激烈的采摘活動的安裝集中在一個非常具體的區域,這些區域有限。This way, the cost of setting up the devices won’t break the bank.

- Goods with a中/高營業額需要非常快速的運輸。

- 小產品易於手動處理。That’s why we talk about packages and crates — most of these products are packed in boxes.

- 已經使用的安裝倉庫管理係統。This software activates the lights, displays the messages on the devices integrated into the shelves,管理庫存並實時更新數據庫。

挑選優勢

The implementation of a pick-to-light system reaps major benefits:

- 它使您的運營更靈活by decreasing the number of operator movements. In addition, it takes advantage of the time previously spent on reading, writing down and checking information to prepare more orders, thereby increasing employee productivity.

- It drastically decreases errors made in order preparation。由於驗證即時,實現了99.5%的準確訂單的百分比。

- It’s the需要最少的培訓的輔助采摘技術for new hires. This facilitates the integration of operators into your installation.

- It updates實時庫存信息。The system transmits stock movements to the WMS, which records them in the database.

- It consists of mature technology that has incorporated more and more possibilities for the design of the devices and the nature of the messages it displays. This, consequently, provides you with enhanced定製選項。

pickversus other technologies

挑選是最熟悉的技術之一,以及語音揀選。盡管這些係統在其操作和硬件方麵都有所不同,但都是voice picking並挑選are geared toward boosting picking ratios, reducing errors and improving overall process efficiency. They represent a natural evolution of射頻挑選, which, indeed, resembles paper picking operations (paper is replaced by the terminal display).

Nevertheless, when deciding between one method and the other, it’s always a good idea to take into account theenvironment in which you’re going to use it:存儲裝置和貨物流動的特殊特征。

Let’s compare both methods more in detail:

| pick | Voice picking | |

| SKU數量 | Designed forhigh concentrations of SKUsin a specific zone with limited dimensions, as the devices are installed in the shelves. |

Most effective in large installations with vast inventories, since it allows operators to cover greater distances. |

| 靈活性 | Obtains optimal results when the design of thepicking areas remains stableover time, as the device is integrated into the shelf. |

Allows for采摘位置和裝修的變化,由於操作員攜帶設備(這裏,它們沒有附在架子上)。 |

| 解決方案成本 | 與裝備的區域的大小成比例,因為這些elements are affixed to the shelves。 |

與運營商的數量成比例,因為每個人攜帶設備。 |

| Productivity | 使您可以達到比率每小時350個訂單線and even more; the light makes it possible for operators to anticipate their movements. |

一般少於300 order lines per hour。 |

| Picking precision | 幾乎100% accuratethanks to enhancements made to pick-to-light devices. |

幾乎100% accuratebecause通過語音檢查strengthen the process. |

| 技術成熟 | 成熟的技術that has continued to evolve since it was first implemented in the 1980s. |

成熟的技術that has improved enormously with voice-recognition software and the elimination of background noise. |

pick有助於及時調度命令,沒有錯誤, thus, resolving two of warehouse managers’ chief concerns. The combination of pick-to-light technology with carton flow racks makes this one of the most powerful solutions for installations with small products, many units per SKU and a high turnover.